Double Module Extrusion Machine for Lithium-Ion Batteries: High-Precision Automated Solution for Battery Manufacturing

2025-06-11

Double Module Extrusion Machine for Lithium-Ion Batteries: High-Precision Automated Solution for Battery ManufacturingAccelerating Global EV Transition: High-Precision Double Extrusion TechnologyAs global demand for lithium-ion batteries surges, rectangular prismatic cells have emerged as the gold standard for high-energy-density and safety applications. Sunkalead’s Fully Automatic Biaxial Module Extrusion Machine is engineered to meet the rigorous demands of modern battery manufacturing, combining PLC automation, force-feedback sensors, and AI-driven workflows to deliver unmatched precision and efficiency.

Key Technical Specifications

Process Technical Parameters

Extrusion Control:PLC-programmed precision (±0.5% accuracy), adjustable force (5–50 tons), stroke range (0–200 mm).

Strapping System:Servo-driven automatic strapping with ±2 N·m tension control, cycle time ≤15 seconds per module.

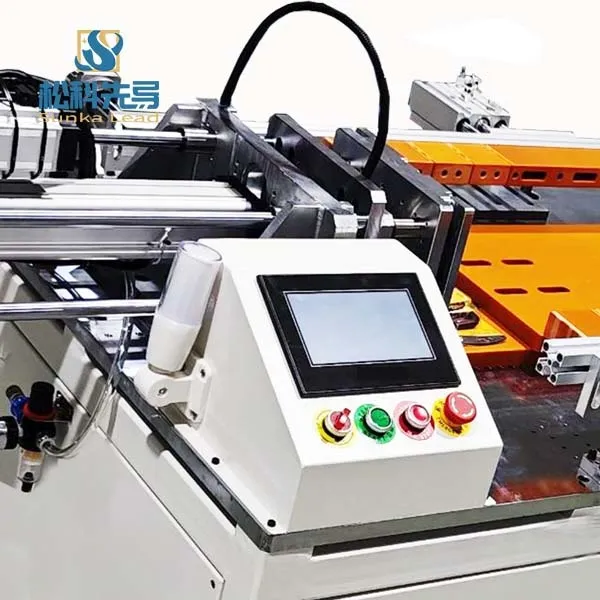

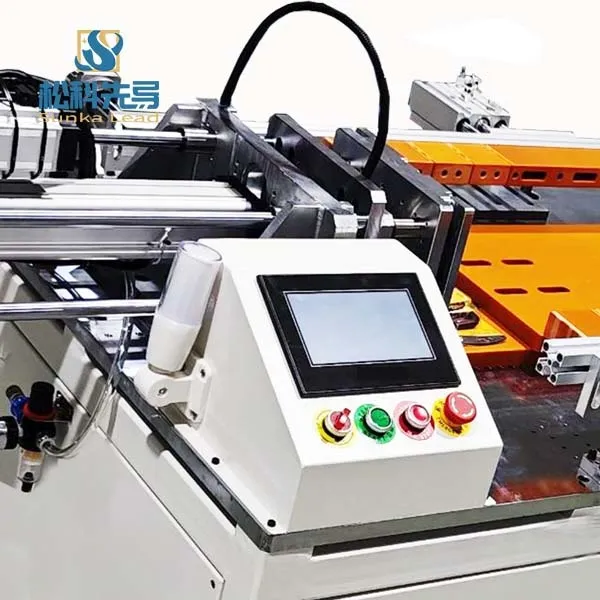

Human-Machine Interface:Pneumatic clamping for part positioning, emergency stop button, and intuitive touchscreen controls.

Data Traceability:USB-exportable reports log pressure/displacement/time parameters, compliant with ISO 9001 standards.

Six Core Advantages

1.Ultra-Precise Control

Ensures inter-electrode spacing tolerance ≤0.2mm, mitigating short-circuit risks in high-voltage modules.

2.Energy-Saving Efficiency

Reduces energy consumption by 60% vs. hydraulic systems, with maintenance costs slashed by 40%.

3.End-to-End Automation

Pre-programmed workflows support 12–16 modules/hour, with "one-click" model switching for 355–505Ah capacity variants.

4.Safety Redundancy

Dual-protection system (pressure relief valves + photoelectric sensors) lowers accident rates by 90%.

5.Scalable Architecture

Modular design integrates with MES systems and future AGV logistics for Industry 4.0 readiness.

6.Global Compliance

Certified to GB/T 36276-2018 safety standards, with thermal/vibration/impact resistance validated for automotive-grade applications.

Application Scenarios

Battery Pack Assembly Lines: Final compression shaping and terminal alignment for prismatic cells

Energy Storage Systems: Reinforced module stacking for large-scale grid storage projects

R&D Laboratories: Material stress testing and process optimization workflows

Customer Testimonial

“Sunkalead’s extruder boosted our module consistency by 35% and cut changeover time from 2 hours to 15 minutes!”

— Technical Director, Leading Chinese EV Battery Manufacturer

Upgrade Your Battery Production Line Today!

Request a Free Consultation: Submit Inquiry

For any inquiries about battery pack assembly line solutions,please don't hesitate to contact us.

Guangdong Sunkalead Intelligent Equipment Co., Ltd.

Double Module Extrusion Machine for Lithium-Ion Batteries: High-Precision Automated Solution for Battery ManufacturingAccelerating Global EV Transition: High-Precision Double Extrusion TechnologyAs global demand for lithium-ion batteries surges, rectangular prismatic cells have emerged as the gold standard for high-energy-density and safety applications. Sunkalead’s Fully Automatic Biaxial Module Extrusion Machine is engineered to meet the rigorous demands of modern battery manufacturing, combining PLC automation, force-feedback sensors, and AI-driven workflows to deliver unmatched precision and efficiency.

Key Technical Specifications

Process Technical Parameters

Extrusion Control:PLC-programmed precision (±0.5% accuracy), adjustable force (5–50 tons), stroke range (0–200 mm).

Strapping System:Servo-driven automatic strapping with ±2 N·m tension control, cycle time ≤15 seconds per module.

Human-Machine Interface:Pneumatic clamping for part positioning, emergency stop button, and intuitive touchscreen controls.

Data Traceability:USB-exportable reports log pressure/displacement/time parameters, compliant with ISO 9001 standards.

Six Core Advantages

1.Ultra-Precise Control

Ensures inter-electrode spacing tolerance ≤0.2mm, mitigating short-circuit risks in high-voltage modules.

2.Energy-Saving Efficiency

Reduces energy consumption by 60% vs. hydraulic systems, with maintenance costs slashed by 40%.

3.End-to-End Automation

Pre-programmed workflows support 12–16 modules/hour, with "one-click" model switching for 355–505Ah capacity variants.

4.Safety Redundancy

Dual-protection system (pressure relief valves + photoelectric sensors) lowers accident rates by 90%.

5.Scalable Architecture

Modular design integrates with MES systems and future AGV logistics for Industry 4.0 readiness.

6.Global Compliance

Certified to GB/T 36276-2018 safety standards, with thermal/vibration/impact resistance validated for automotive-grade applications.

Application Scenarios

Battery Pack Assembly Lines: Final compression shaping and terminal alignment for prismatic cells

Energy Storage Systems: Reinforced module stacking for large-scale grid storage projects

R&D Laboratories: Material stress testing and process optimization workflows

Customer Testimonial

“Sunkalead’s extruder boosted our module consistency by 35% and cut changeover time from 2 hours to 15 minutes!”

— Technical Director, Leading Chinese EV Battery Manufacturer

Upgrade Your Battery Production Line Today!

Request a Free Consultation: Submit Inquiry

For any inquiries about battery pack assembly line solutions,please don't hesitate to contact us.

Guangdong Sunkalead Intelligent Equipment Co., Ltd.