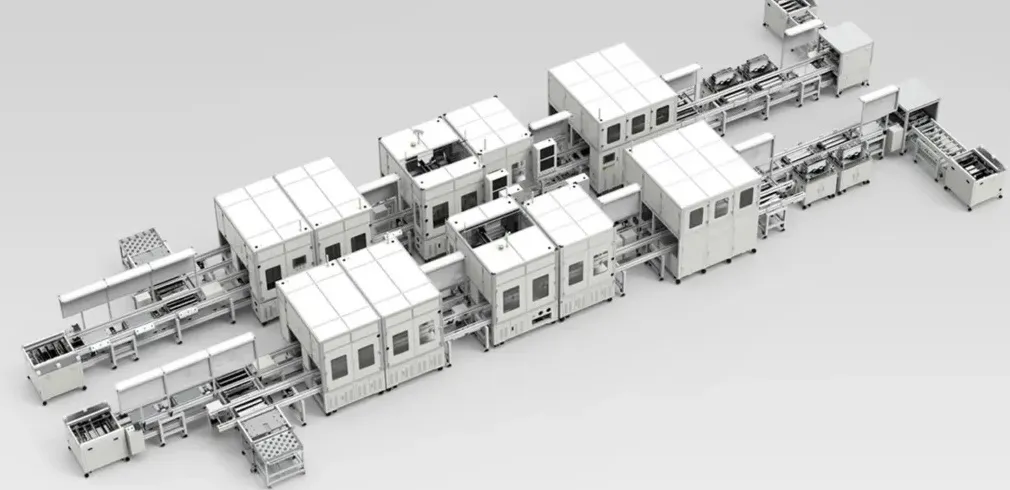

Pouch Battery Pack Assembly Line

The soft-pack battery assembly line is a core component in the production of lithium-ion batteries, with its positioning centered around high energy density, lightweight design, and flexible manufacturing. As the performance demands for batteries in electric vehicles and energy storage systems increase, soft-pack batteries, leveraging the advantages of aluminum-plastic film encapsulation (which is over 30% lighter than traditional steel casings), have become the mainstream choice for adapting to 800V high-voltage platforms and CTP (Cell to Pack) technology.

The soft-pack battery assembly line is a core component in the production of lithium-ion batteries, with its positioning centered around high energy density, lightweight design, and flexible manufacturing. As the performance demands for batteries in electric vehicles and energy storage systems increase, soft-pack batteries, leveraging the advantages of aluminum-plastic film encapsulation (which is over 30% lighter than traditional steel casings), have become the mainstream choice for adapting to 800V high-voltage platforms and CTP (Cell to Pack) technology.

|

Pouch Battery Pack Assembly Line

|

Pouch Battery Pack Assembly Line Process flow

The soft-pack battery assembly line comprises six core processes, achieving full-process closed-loop control through technologies such as machine vision and digital twins.

Cell Preprocessing and Sorting

- Cell Screening: High-precision testing equipment (e.g., HIOKI charge-discharge testers) is used to grade and match cells based on capacity, internal resistance, and voltage, ensuring an intra-group variation of ≤0.5%.

- Tab Processing: Laser cutting machines trim tabs to a precision of ±0.05mm, with plasma cleaning to remove surface oxides, enhancing subsequent welding quality.

Stacking and Module Assembly

- Z-Fold Stacking Technology: Robotic arms stack cells according to preset programs, employing a separator-cell alternating lamination process, increasing energy density by 5-8% compared to wound structures.

- Flexible Fixture Design: Supports dynamic adjustment of cell dimensions (e.g., length 150-300mm, thickness 3-8mm), reducing changeover time to 20 minutes (e.g., Tesscorn solution).

High-Precision Welding Process

- Hybrid Welding Technology: Combines laser welding (tab connection) and ultrasonic welding (busbar integration), controlling the heat-affected zone (HAZ) to within 0.3mm, with a yield rate of 99.7%.

- Real-Time Monitoring System: Infrared thermal imaging detects temperature fluctuations at weld points, automatically compensating energy parameters to avoid cold/overwelding.

Thermal Management and Encapsulation Integration

- Cooling Plate Assembly: A vision positioning system guides the alignment of cooling plates with cells, ensuring a gap of ≤0.1mm and a thermal paste coating thickness precision of ±0.02mm.

- Aluminum-Laminate Film Sealing: Dual-station alternating sealing (top + side), with helium leak detectors ensuring sealing integrity, achieving a leakage rate of ≤1×10⁻⁶ Pa·m³/s.

Final Inspection and Intelligent Control

- EOL Testing: Simulates real-world conditions with 0.5C-3C charge-discharge cycles, using AI algorithms to analyze voltage decay curves and predict battery life (error ±2%).

- Data Traceability: The MES system binds individual cell IDs, enabling real-time retrieval of full lifecycle data (e.g., production batches, test results).

|

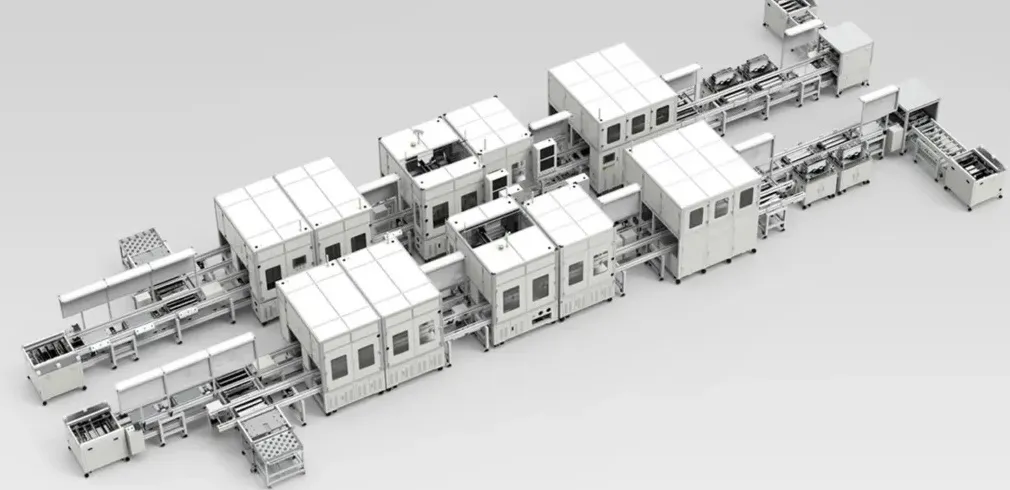

Pouch Battery Pack Assembly Line

|

Pouch Battery Pack Assembly Line Process flow

The soft-pack battery assembly line comprises six core processes, achieving full-process closed-loop control through technologies such as machine vision and digital twins.

Cell Preprocessing and Sorting

- Cell Screening: High-precision testing equipment (e.g., HIOKI charge-discharge testers) is used to grade and match cells based on capacity, internal resistance, and voltage, ensuring an intra-group variation of ≤0.5%.

- Tab Processing: Laser cutting machines trim tabs to a precision of ±0.05mm, with plasma cleaning to remove surface oxides, enhancing subsequent welding quality.

Stacking and Module Assembly

- Z-Fold Stacking Technology: Robotic arms stack cells according to preset programs, employing a separator-cell alternating lamination process, increasing energy density by 5-8% compared to wound structures.

- Flexible Fixture Design: Supports dynamic adjustment of cell dimensions (e.g., length 150-300mm, thickness 3-8mm), reducing changeover time to 20 minutes (e.g., Tesscorn solution).

High-Precision Welding Process

- Hybrid Welding Technology: Combines laser welding (tab connection) and ultrasonic welding (busbar integration), controlling the heat-affected zone (HAZ) to within 0.3mm, with a yield rate of 99.7%.

- Real-Time Monitoring System: Infrared thermal imaging detects temperature fluctuations at weld points, automatically compensating energy parameters to avoid cold/overwelding.

Thermal Management and Encapsulation Integration

- Cooling Plate Assembly: A vision positioning system guides the alignment of cooling plates with cells, ensuring a gap of ≤0.1mm and a thermal paste coating thickness precision of ±0.02mm.

- Aluminum-Laminate Film Sealing: Dual-station alternating sealing (top + side), with helium leak detectors ensuring sealing integrity, achieving a leakage rate of ≤1×10⁻⁶ Pa·m³/s.

Final Inspection and Intelligent Control

- EOL Testing: Simulates real-world conditions with 0.5C-3C charge-discharge cycles, using AI algorithms to analyze voltage decay curves and predict battery life (error ±2%).

- Data Traceability: The MES system binds individual cell IDs, enabling real-time retrieval of full lifecycle data (e.g., production batches, test results).

Prismatic Battery Pack Assembly Line Application

Electric Vehicles (EVs) Electric Vehicles (EVs) |

Electric Golf Cart Electric Golf Cart |

Electric Boat Electric Boat |

Electric Firefighting Robot Electric Firefighting Robot |

Unmanned Submersibles Unmanned Submersibles |

Automated Guided Vehicles Automated Guided Vehicles |

UPS UPS |

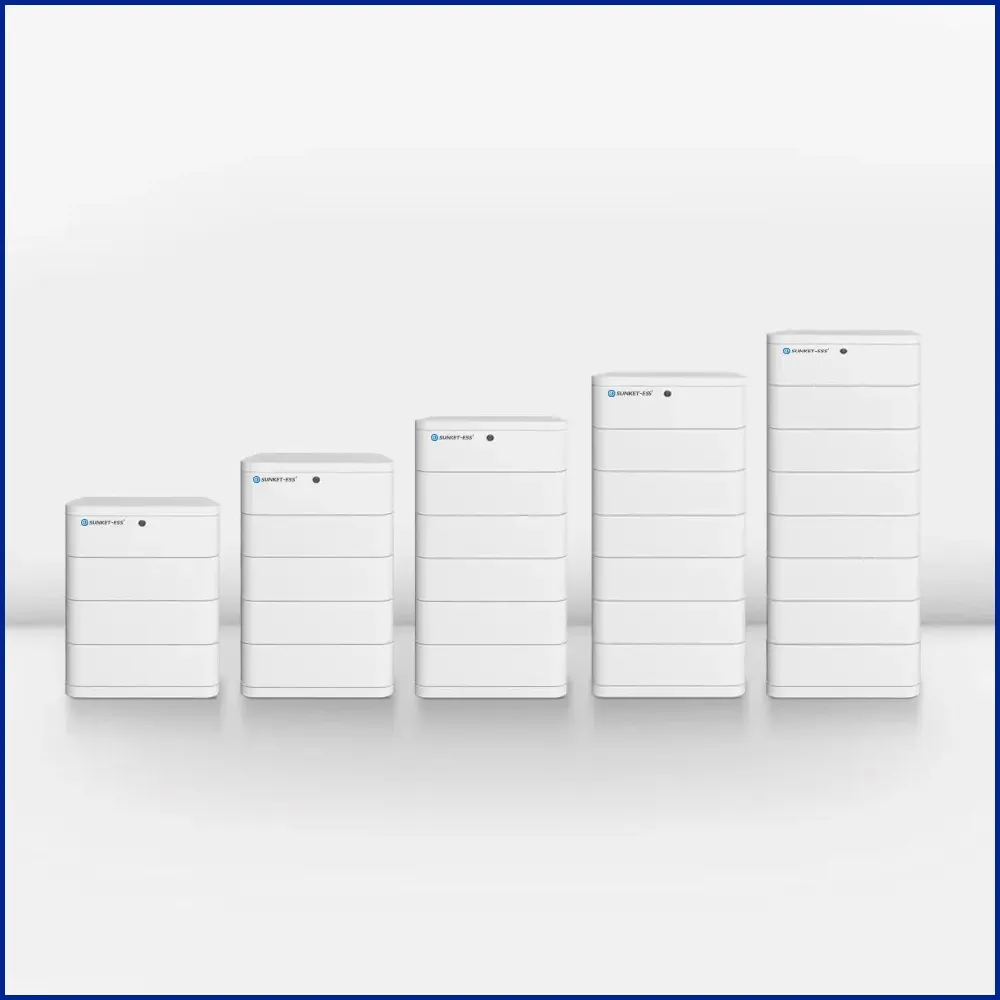

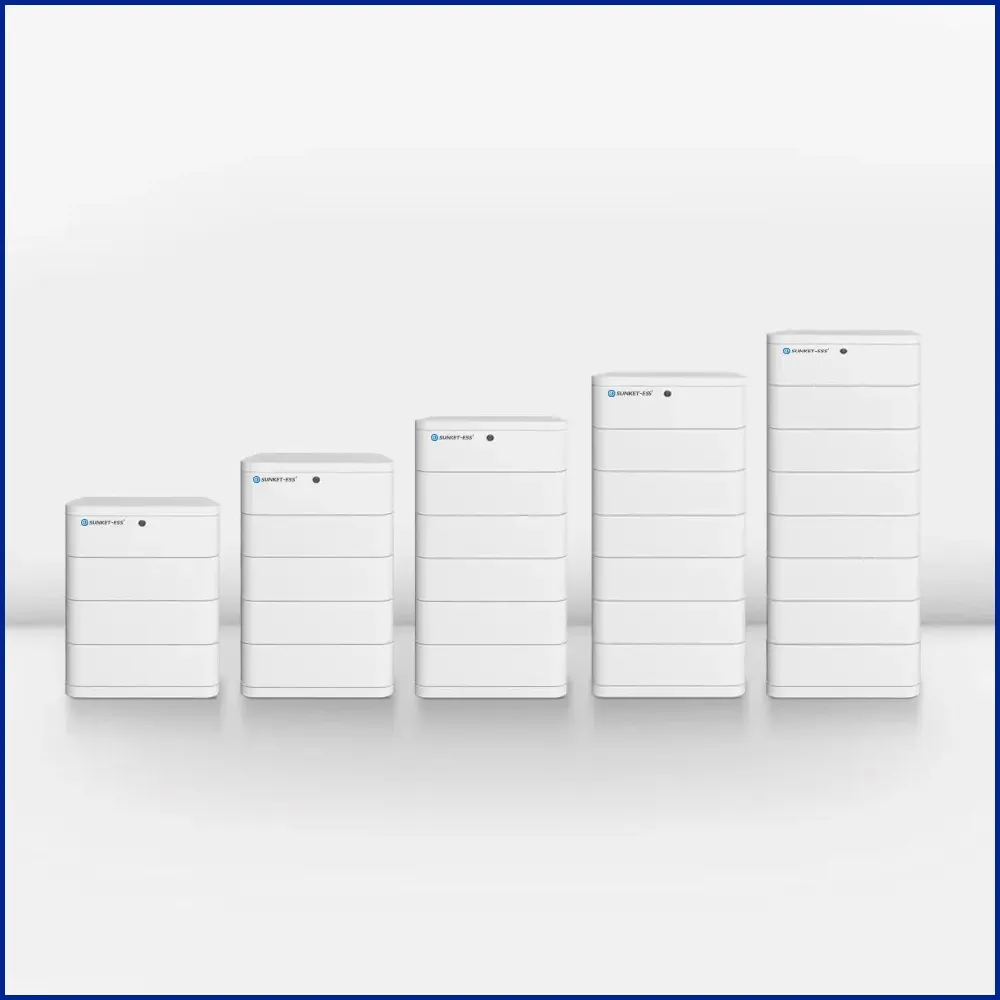

Home Energy Storage Home Energy Storage |

Communication Base Station Communication Base Station |

Container Energy Storage Container Energy Storage |

Mobile Ventilators Mobile Ventilators |

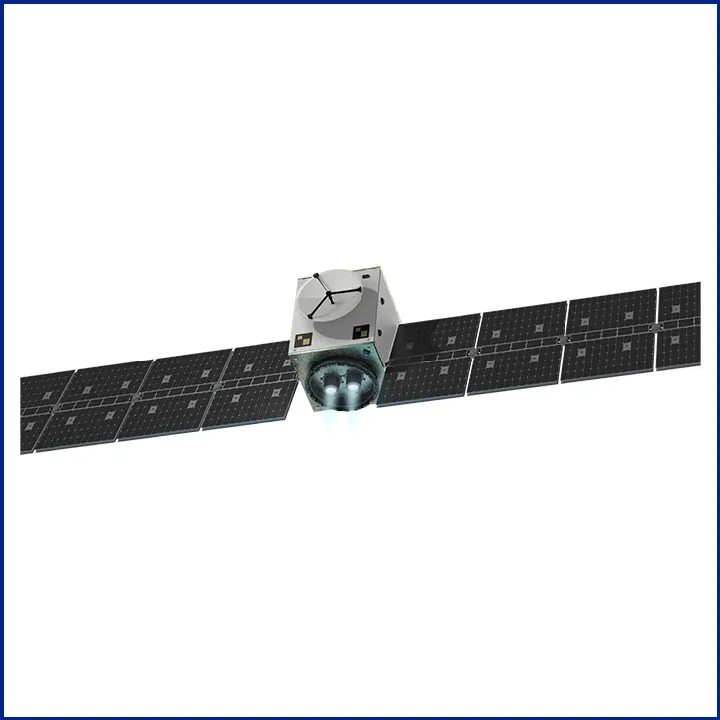

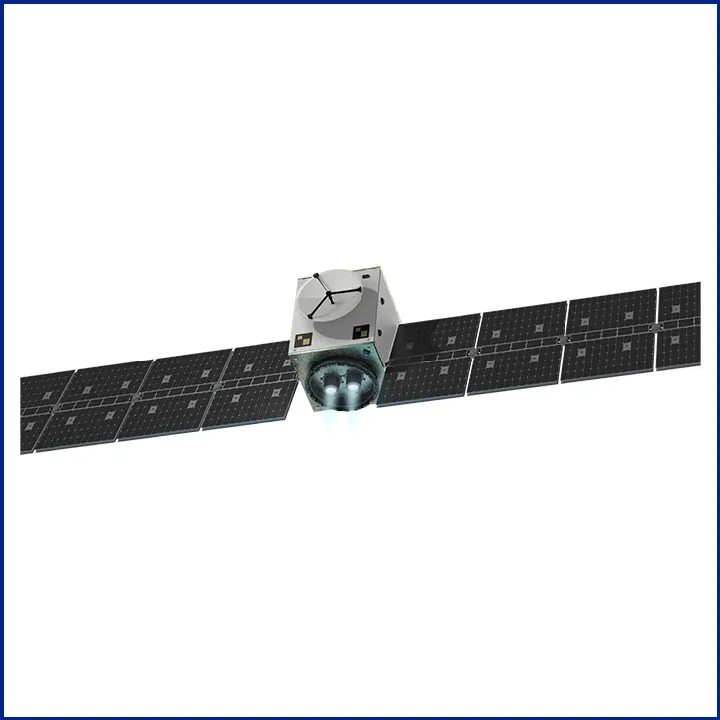

Satellite Power Systems Satellite Power Systems |

Prismatic Battery Pack Assembly Line Application

Electric Vehicles (EVs) Electric Vehicles (EVs) |

Electric Golf Cart Electric Golf Cart |

Electric Boat Electric Boat |

Electric Firefighting Robot Electric Firefighting Robot |

Unmanned Submersibles Unmanned Submersibles |

Automated Guided Vehicles Automated Guided Vehicles |

UPS UPS |

Home Energy Storage Home Energy Storage |

Communication Base Station Communication Base Station |

Container Energy Storage Container Energy Storage |

Mobile Ventilators Mobile Ventilators |

Satellite Power Systems Satellite Power Systems |

Ultra-High Production Efficiency

Utilizing digital twin technology to optimize production cycles, the single-line capacity can reach 15~30 PPM (15~30 modules per minute), representing an 80% improvement over traditional production lines.

The AGV+RGV logistics system enables automatic material distribution, reducing manual intervention by 80%.

Extreme Safety Design

Multi-sensor linkage monitoring (temperature, pressure, gas concentration) ensures abnormal cells are automatically isolated within 0.5 seconds, with a failure rate of ≤0.01%.

Thermal runaway protection: Dual barriers with ceramic silicone gaskets and fire-resistant coatings can delay thermal spread by ≥30 minutes.

Flexibility and Scalability

Compatible with multiple cell chemistries (LFP, NCM, solid-state batteries), reducing production line modification costs by 60%.

Modular design supports flexible capacity expansion (e.g., from 1GWh to 5GWh), suitable for both small-batch customization and large-scale mass production.

Green Manufacturing Upgrade

Laser cutting and welding processes minimize copper/aluminum waste, achieving a material utilization rate of 98%.

Exhaust gas treatment systems (e.g., RTO incineration) ensure VOC emissions ≤10mg/m³, complying with the EU Battery Regulation environmental standards.

Ultra-High Production Efficiency

Utilizing digital twin technology to optimize production cycles, the single-line capacity can reach 15~30 PPM (15~30 modules per minute), representing an 80% improvement over traditional production lines.

The AGV+RGV logistics system enables automatic material distribution, reducing manual intervention by 80%.

Extreme Safety Design

Multi-sensor linkage monitoring (temperature, pressure, gas concentration) ensures abnormal cells are automatically isolated within 0.5 seconds, with a failure rate of ≤0.01%.

Thermal runaway protection: Dual barriers with ceramic silicone gaskets and fire-resistant coatings can delay thermal spread by ≥30 minutes.

Flexibility and Scalability

Compatible with multiple cell chemistries (LFP, NCM, solid-state batteries), reducing production line modification costs by 60%.

Modular design supports flexible capacity expansion (e.g., from 1GWh to 5GWh), suitable for both small-batch customization and large-scale mass production.

Green Manufacturing Upgrade

Laser cutting and welding processes minimize copper/aluminum waste, achieving a material utilization rate of 98%.

Exhaust gas treatment systems (e.g., RTO incineration) ensure VOC emissions ≤10mg/m³, complying with the EU Battery Regulation environmental standards.